5 Easy Facts About 24hr Media Described

5 Easy Facts About 24hr Media Described

Blog Article

Not known Details About 24hr Media

Table of ContentsHow 24hr Media can Save You Time, Stress, and Money.5 Simple Techniques For 24hr Media24hr Media for Dummies10 Simple Techniques For 24hr MediaThe Ultimate Guide To 24hr Media

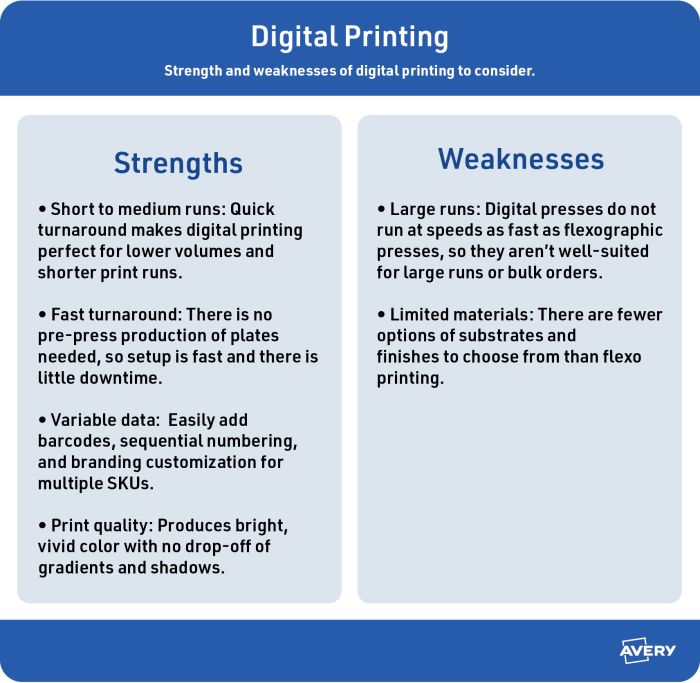

Offset, gravure printing and flexography are the most typical sorts of conventional printing in the product packaging room and each involves transferring the photo from a plate to the surface area. To do this, first the plate needs to be created, and it is the development of these plates that take some time, and cost money.According to PMMI, digital printing enables brand names and manufacturers to respond swiftly to client needs while enhancing the supply chain, decreasing warehousing expense and waste, and appreciating faster time to market. That all sounds wonderful, but exactly how does this technology do all that? The significant differentiator of these innovations is that there are no set-up costs and no plates with digital printing.

According to Wikipedia, the best distinction between electronic printing and traditional methods such as lithography, flexography, gravure, or letterpress is that there is no need to change printing plates in electronic printing, whereas in these analog printing methods the plates are repeatedly replaced. This leads to quicker turnaround time and lowers expense when utilizing digital printing.

Fast manufacturing implies getting your product to market faster. It likewise implies it's easier and faster to make changes later, when you change a recipe, include a SKU, or produce seasonal packaging. Digital printing is extremely flexible, so it's very easy to make modifications to the bundle design quickly. All of it goes back to home plates.

Some Known Factual Statements About 24hr Media

Extra inventory can mean even more waste down the roadway. With conventional printing approaches, short-run printing is just not possible. Since an excellent design can make or damage your product, electronic printing constantly develops top quality, clear and vivid graphics each time. Digital printing on flexible pouches includes the intense, dynamic, and accurate graphics that practically bid customers to connect and touch them.

Loading ... Are you knowledgeable about the benefits of electronic printing? Review on to understand when electronic printing can be the most effective possible option for your business. Do you know why digital printing has ended up being the preferred option of some businesses? Both balanced out and electronic printing have their location in the printing market.

In this write-up, we will review the advantages of electronic printing to aid you better comprehend if digital printing is just what you require. Basically - digital printing prints material straight onto the paper. It gets rid of some actions required in countered printing, like creating metal plates. Inkjet printers utilize small nozzles to spray beads of ink onto the substratum.

Fascination About 24hr Media

As electronic printing frequently evolves, it uses extra possibilities and greater result high quality every day. In some instances, the print high quality can be as high as to counter printing.

For countered printing, if any error goes unnoticed before producing home plates, there will be a high price of developing a new one. But, with digital printing, this is not the situation. Although everyone always hopes there will certainly be indisputable, recognizing the cost of remedying them if they happen is always a great idea.

This indicates every item will look the very same, so the possibility you will certainly need to throw out any one of them as a result of variances is low. Additionally, given that a proofing sample is published on the very same device as the product itself, shade proofing is very accurate. Any type of troubles with shade will show up on the proof, and thus it will be feasible to transform it before publishing the entire run.

Top Guidelines Of 24hr Media

Digital printing, on the various other hand, needs marginal configuration. There are less pre-press treatments, so the initial setup time is dramatically decreased. As an outcome, turn-around is noticeably much faster. Your order can be refined as quickly as you submit it. This is terrific when you are in a rush to obtain your printed products.

This implies even more ask for electronic on-demand print production. Every client values a customized message. Among the benefits of digital printing is that personalizing your advertising and marketing materials couldn't be easier. Affordable, smaller sized sets allow services to tailor each order. Have a back-to-school sale? Make a leaflet to target parents and an additional one to target the pupils.

Digital printing is the ideal option for variable data printing, like personalized codes and addresses on direct-mail advertising. With electronic printing, it is much less bothersome to make final changes like this to your style. In some cases the most effective type of communication is not electronic. In these situations, counting on digital printing can make certain these orders have a minimal environmental influence.

The 2-Minute Rule for 24hr Media

There is likewise no need to clean home plates after printing. The benefits of digital printing include that there is no waste from additional or remaining ink, paper, or chemicals due to the fact that only what's required gets published. - for really short runs, electronic printing is the means to go, certainly.

Gone are the days of intricate setups and lengthy turnaround times - electronic printing has revolutionised the print sector. The printing globe has come a long way given that the days of Gutenberg's printing press. The new typical is streamlined procedures and cost-efficient options for printing onto virtually anything you can consider.

Report this page